News

Luoyang Bozhi Delivers OEM Excellence for Argentina: Technical Synergy Powers Complex Warehouse Automation

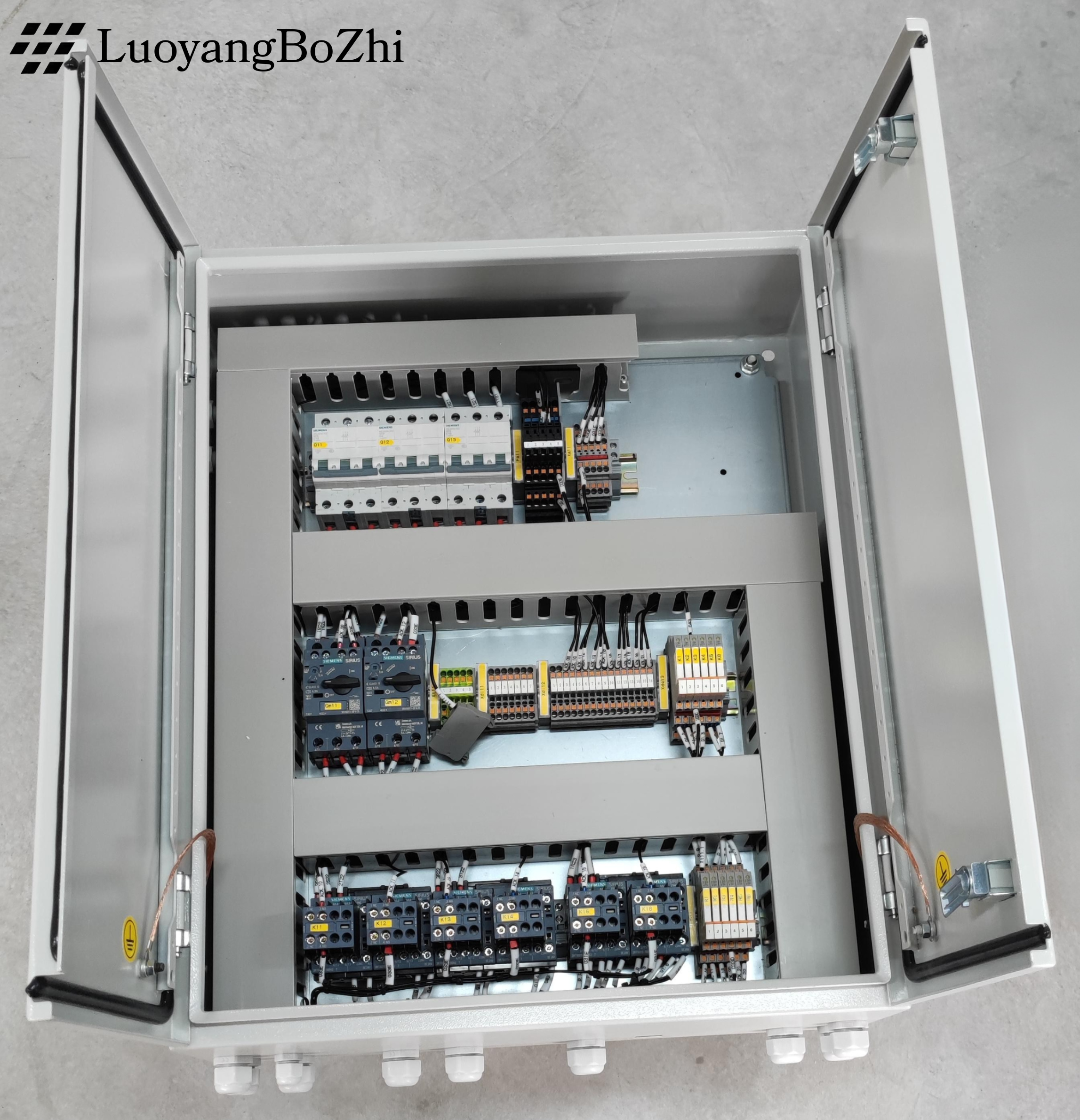

As a premium OEM partner, Luoyang Bozhi Automation & Control Technology Co., Ltd. has successfully delivered 26 customized control cabinets to a leading Argentinian warehousing enterprise. Confronting 32 technical conflicts in initial client blueprints, Bozhi engineers proposed 19 critical optimizations, achieving 100% first-pass electrical testing and delivering 12 days ahead of schedule. This marks the second collaboration , with client executives scheduling a Q4 China visit to discuss strategic partnership enhancement.

Reverse-Engineering Innovation: From OEM Execution to Technical Co-Creation

Bozhi demonstrated unique OEM capabilities:

- Blueprint Refinement: Redesigned PLC cabinet wire channels to boost wiring efficiency by 40%;

- Process Enhancement: Exceeded client's IEC 60204-1 requirements with self-initiated EN 61439-3 seismic certification;

- Smart Testing: Custom test benches reduced factory acceptance testing from 72 to 28 hours with ≤0.1% tolerance.

Precision Manufacturing Under Time Constraints

To meet urgent delivery demands (35% shorter than standard lead times), Bozhi executed:

- 24/3-shift operations with 15 dedicated technicians

- Laser-guided wiring replacing manual processes, tripling daily output

- Real-time Chinese-Spanish collaboration platform closing design changes within 2 hours

The client's PM noted: "Bozhi's engineering foresight surpassed typical OEMs. Their proactive cable management optimization saved us 17% in post-installation costs."

From Manufacturing Partnership to Smart Alliance

The upcoming China visit will focus on:

- Establishing South America's first Industry 4.0 control cabinet joint lab

- Developing Spanish-language smart diagnostic systems

- Building local pre-assembly centers in Argentina

The CEO stated: "We're redefining OEM partnerships – not just as manufacturers, but as strategic enablers of our clients' technological evolution."